A deep dive into Computer-Aided Engineering and our company.

At its core, Airovex is not just about engineering solutions; it’s about a philosophy that combines meticulous attention to detail with an imaginative approach. This blend leads to a unique service offering that is not just efficient but also highly creative. That being said, Computer-Aided Engineering (CAE) represents the forefront of engineering innovation. It’s a field that has revolutionized the way products are designed, analyzed, and optimized. By leveraging advanced software tools, CAE enables engineers to simulate real-world conditions and predict product performance long before a physical prototype is built.

This not only saves time and resources but also opens new possibilities for innovation and design excellence. Our utilization of CAE is a testament to the forward-thinking approach we pursue. By integrating CAE into our services, we as a company can offer our clients a comprehensive and detailed analysis of their products, ensuring that every design meets the highest standards of quality and performance. This approach is central to our mission to deliver superior engineering solutions that are both innovative and sustainable.

This post is set to explore the intricate world of Computer-Aided Engineering at Airovex. We will delve into what CAE is, its benefits, and how Airovex leverages this technology to bring visionary ideas to life. From the origins of CAE in the aerospace and Formula 1 industries to its applications in a myriad of sectors, we aim to provide a comprehensive overview that showcases the immense capabilities and potential of CAE in modern engineering. In the following sections, we will embark on a journey through the various facets of CAE, unveiling its complexities and highlighting its profound impact on the world of engineering.

What is Computer-Aided Engineering (CAE)?

Computer-Aided Engineering (CAE) is at the heart of modern engineering, a term that encompasses a vast array of tools and techniques used to design, simulate, and analyze products and processes.

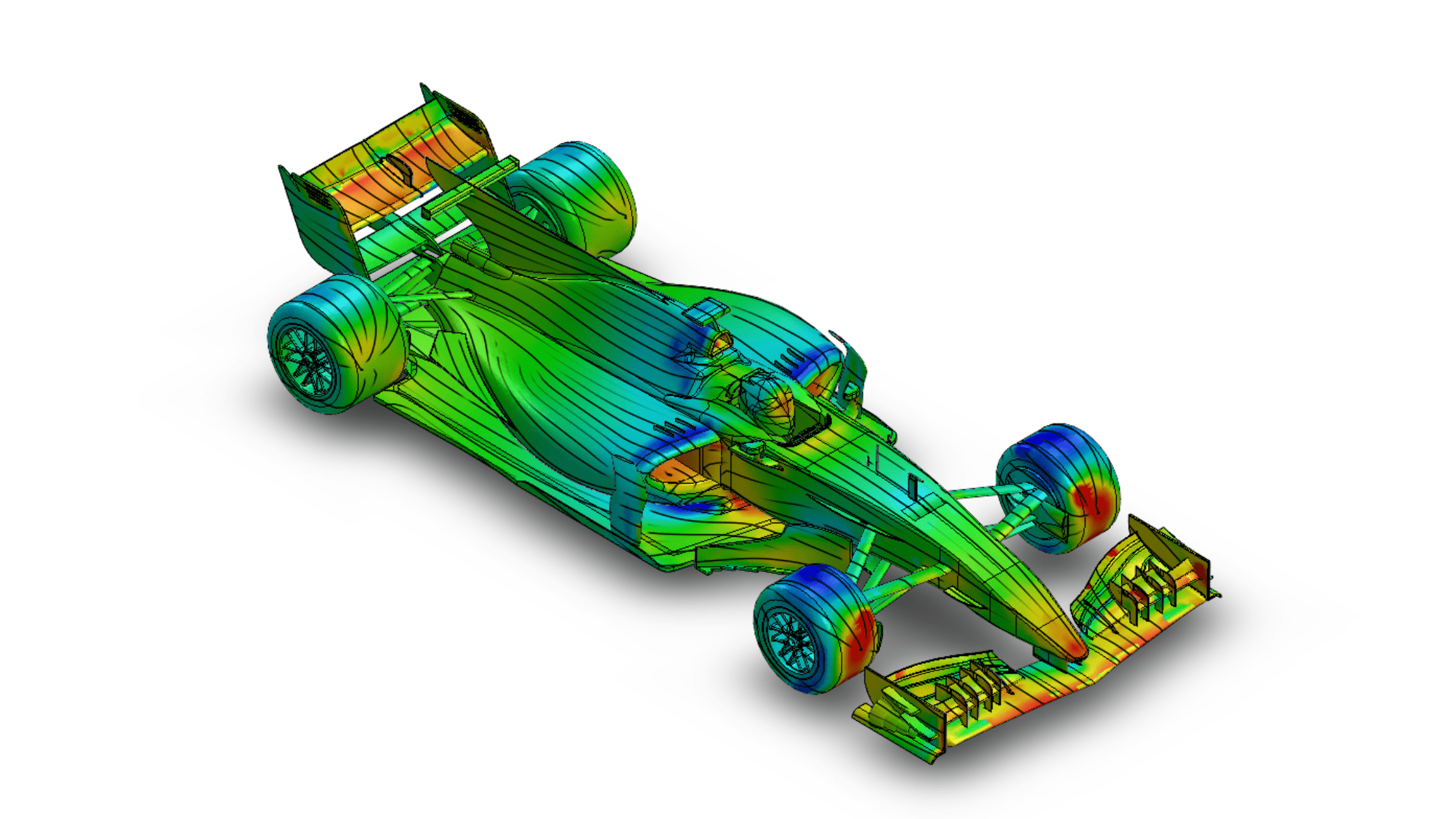

In our work at Airovex, we leverage CAE as a pivotal technology, enabling us to explore and optimize design solutions in a virtual environment. CAE goes beyond traditional design methods, allowing us to predict performance and solve potential problems before they arise in the physical world. CAE includes a range of tools such as Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA), each serving a unique purpose. With CFD, we can analyze fluid flow and heat transfer, while FEA enables us to study structural and thermal stresses. These tools are not just about simulation; they are about gaining deeper insights into how products will perform under various conditions.

The evolution of CAE has been a game-changer for us. What began as a tool for analyzing automotive and aerospace designs has now become a staple in countless industries. This progression reflects the increasing complexity of products and the need for more sophisticated design and analysis techniques. Our approach to CAE has evolved alongside these advancements, ensuring that we stay at the forefront of technological innovation.

Incorporating CAE into our design process marks a significant shift in how we approach engineering challenges. It allows us to create detailed models of products, simulate real-world scenarios, and make data-driven decisions. This approach not only enhances the efficiency of our design process but also significantly reduces the reliance on physical prototypes, leading to cost savings and a faster time to market.

The impact of CAE on the engineering landscape cannot be overstated. It has transformed the way we conceptualize, design, and validate products. By predicting and analyzing performance early in the design process, we can identify potential issues, optimize designs for performance and sustainability, and ultimately deliver superior products to our clients. Looking ahead, we see CAE as a continually evolving field, with emerging technologies like artificial intelligence and machine learning poised to further enhance its capabilities. As we embrace these advancements, our commitment to delivering innovative and sustainable engineering solutions remains steadfast.

CAE is not just a tool for us, it’s a pathway to engineering excellence.

The Role of CAE in Product Development at Airovex

At Airovex, we integrate Computer-Aided Engineering (CAE) into every stage of our product development process. From initial concept to final design, CAE is a constant companion, providing us with valuable insights and data. This integration is crucial for us to maintain a high standard of precision and innovation in our work.

One of the most exciting aspects of CAE for us is its ability to turn abstract ideas into tangible products. Through innovative design and expert engineering, CAE tools like CAD (Computer-Aided Design) play a pivotal role. These tools enable us to visualize and refine our ideas in a virtual space, bringing them closer to reality with each iteration. As wyou might expect, performance is key in engineering, and CAE is instrumental in optimizing it. Using simulation tools, we can predict how a product will perform in various scenarios, identify potential weaknesses, and make improvements. This process not only enhances the product’s functionality but also ensures its reliability and safety.

CAE has revolutionized the way we approach the design process. By allowing us to simulate and test different scenarios digitally, we can significantly reduce the number of physical prototypes needed. This not only speeds up the development process but also makes it more cost-effective and sustainable. Our application of CAE is not limited to a single industry. Whether it’s aerospace, automotive, marine, or consumer electronics, CAE enables us to tailor our solutions to meet the specific requirements of each sector. This versatility is essential for us to provide our clients with solutions that are not just innovative but also perfectly aligned with their needs.

Each project we undertake is a testament to our engineering expertise, and CAE is a significant part of that story. By leveraging the power of CAE, we can push the boundaries of what’s possible, transforming visionary ideas into revolutionary realities.

Why we use CAE at Airovex Engineering:

In a few words:

- Enhanced Accuracy and Predictability.

- Reduced Time and Costs.

- Innovation and Design Freedom.

- Sustainability and Environmental Responsibility.

- Meeting Industry-Specific Needs

- Continuous Improvement and Learning.

Going into greater detail, one of the most significant benefits of using CAE for us at Airovex is the enhanced accuracy and predictability it brings to our engineering projects. By simulating real-world conditions, we can see how a product will perform under various scenarios. This foresight is invaluable, as it helps us identify and rectify potential issues early in the design process, ensuring the final product meets our high standards of quality and reliability.

CAE significantly reduces the time and costs associated with traditional product development. By relying less on physical prototypes and more on digital simulations, we can streamline our development process, saving both time and resources. This efficiency not only benefits us but also our clients, who enjoy quicker turnaround times and cost-effective solutions. CAE opens up a world of innovation and design freedom for us. With the ability to test and modify designs in a virtual environment, we can explore more creative and daring ideas that might be too costly or risky to prototype physically. This freedom allows us to push the boundaries of conventional design and offer our clients truly unique and innovative products.

Sustainability is a core value at Airovex, and CAE plays a crucial role in helping us design more sustainable products. By optimizing materials and processes through simulation, we can minimize waste and reduce the environmental impact of our products. This approach aligns with our commitment to environmental responsibility and the creation of products that are not only innovative but also eco-friendly. Similarly, the versatility of CAE enables us to meet the specific needs of various industries. Whether it’s designing high-performance aerospace components or crafting intricate consumer electronics, CAE provides us with the tools to tailor our solutions to each industry’s unique challenges and requirements.

Finally, CAE fosters an environment of continuous improvement and learning at Airovex. The data and insights gained from simulations inform our future projects, enabling us to constantly refine our skills and techniques. This cycle of learning and improvement is essential for staying ahead in the fast-paced world of engineering and technology.

A quick look into different CAE applications in high-precision Fields

The roots of Computer-Aided Engineering can be traced back to the aerospace industry, where precision and safety are paramount. In this high-stakes environment, CAE emerged as a critical tool for designing and testing aircraft components under various conditions. At Airovex, we draw inspiration from these aerospace origins, applying the same level of precision and reliability to our engineering projects, regardless of the industry.

Another example is the high-octane world of Formula 1 racing, which has also played a significant role in the evolution of CAE. Here, milliseconds and millimeters make the difference between victory and defeat. The precision and efficiency required in Formula 1 have greatly influenced the development of our CAE tools, especially in areas like Computational Fluid Dynamics (CFD), allowing us to achieve unparalleled accuracy in our projects.

Other applications of CAE have grown far beyond its aerospace and Formula 1 origins. Today, we use CAE in a variety of sectors, from marine engineering to consumer electronics. Each industry presents unique challenges, and CAE equips us with the versatility to address these with tailored solutions. Whether it’s optimizing the hydrodynamics of a boat or ensuring the thermal stability of electronic devices, CAE is our go-to tool. We look at CAE as a comprehensive approach to problem-solving and innovation. In our work at Airovex, CAE enables us to not only simulate and test designs but also to analyze data, predict outcomes, and make informed decisions. This integral approach is crucial for delivering solutions that are not just viable but also ahead of their time.

As we look to the future, the integration of emerging technologies like AI and machine learning with CAE is set to unlock even more potential. These advancements will enhance our ability to simulate complex scenarios with greater accuracy and efficiency. We are excited about the prospects of integrating these technologies into our CAE toolkit, further solidifying our commitment to innovation and excellence in engineering.

Shaping the Future with CAE

As we’ve explored throughout this blog post, Computer-Aided Engineering (CAE) is more than just a set of tools—it’s a gateway to innovation, efficiency, and sustainability in engineering. At Airovex, our deep commitment to leveraging the full potential of CAE has enabled us to push the boundaries of what’s possible, transforming visionary ideas into revolutionary realities.

Our journey through the intricate world of CAE reflects our unwavering commitment to excellence. From enhancing product performance to fostering innovation and ensuring sustainability, CAE stands at the core of our operations. It empowers us to meet the complex challenges of modern engineering with confidence and precision.

We see ourselves not just as service providers but as partners in innovation. We believe that the true power of CAE is unlocked when we collaborate closely with our clients, understanding their vision and aligning our expertise to realize it. This partnership approach is fundamental to achieving outstanding results that exceed expectations. Our application of CAE extends across a broad spectrum of industries, demonstrating its versatility and adaptability. Whether it’s aerospace, automotive, marine, or consumer electronics, we tailor our CAE solutions to meet the unique needs of each sector, delivering targeted, effective results.

Looking ahead, we are excited about the future of CAE and its role in shaping the next generation of engineering solutions. As technology continues to evolve, so too will our use of CAE, ensuring that we remain at the cutting edge of engineering innovation. We are committed to exploring new possibilities, pushing technological boundaries, and contributing to a more sustainable and efficient future.

We invite you to join us on this exciting journey. Whether you’re facing a complex engineering challenge or looking to innovate, our team at Airovex is ready to bring our CAE expertise to your project. Together, we can create something truly exceptional.

Thank you for joining us on this deep dive into Computer-Aided Engineering. We hope this blog post has illuminated the vast possibilities that CAE offers and how, at Airovex, we harness these capabilities to deliver superior engineering solutions. We look forward to the opportunity to collaborate and innovate together.