Over the past few years, hydrofoiling, especially wingfoiling, has surged from niche curiosity to mainstream water sport. Whether it’s weekend warriors gliding effortlessly over the chop or professional athletes carving tight arcs in high wind, foils are rewriting the rulebook of marine performance.

But as the sport grows, so does the demand for gear that’s not just fast, but intuitive. That’s where user-centric design comes in. Borrowed from the world of software and consumer tech, this philosophy should be embraced by high-performance gear manufacturers. It’s not just about raw numbers anymore, it’s about how real people ride.

For companies like us, which blend engineering precision with athlete-first thinking, this marks an important change: no longer is foil design only about fluid dynamics and material science, it’s also about listening to the users and embracing their feedback. For us at Airovex, collaboration is not transactional; it’s relational. When we begin a project, we don’t simply take a design brief, we immerse ourselves in your vision, aligning with your goals and exploring the broader impact of the challenge at hand. For example, in a project focused on developing new iterations of competitive sails for J/70 boats, our team worked alongside clients to map out every step of the design journey, ensuring that environmental, technical, and economic factors were all addressed holistically.

We know that innovation often lies in the tension between constraints and creativity. Our collaborative approach brings together engineers, designers, and domain experts, enabling us to explore unconventional ideas while staying grounded in real-world feasibility. This partnership-driven mindset ensures every solution we deliver is not only innovative but tailored to your specific needs.

User-Centric Design in the Marine World.

Over the past few years, hydrofoiling, especially wingfoiling, has surged from niche curiosity to mainstream water sport. Whether it’s weekend warriors gliding effortlessly over the chop or professional athletes carving tight arcs in high wind, foils are rewriting the rulebook of marine performance.

But as the sport grows, so does the demand for gear that’s not just fast, but intuitive. That’s where user-centric design comes in. Borrowed from the world of software and consumer tech, this philosophy should be embraced by high-performance gear manufacturers. It’s not just about raw numbers anymore, it’s about how real people ride.

For companies like us, which blend engineering precision with athlete-first thinking, this marks an important change: no longer is foil design only about fluid dynamics and material science, it’s also about listening to the users and embracing their feedback. For us at Airovex, collaboration is not transactional; it’s relational. When we begin a project, we don’t simply take a design brief, we immerse ourselves in your vision, aligning with your goals and exploring the broader impact of the challenge at hand. For example, in a project focused on developing new iterations of competitive sails for J/70 boats, our team worked alongside clients to map out every step of the design journey, ensuring that environmental, technical, and economic factors were all addressed holistically.

We know that innovation often lies in the tension between constraints and creativity. Our collaborative approach brings together engineers, designers, and domain experts, enabling us to explore unconventional ideas while staying grounded in real-world feasibility. This partnership-driven mindset ensures every solution we deliver is not only innovative but tailored to your specific needs.

Redefining and testing the limits.

The real challenge? Turning subjective impressions into objective specs. Here’s how rider feedback commonly maps to core foil characteristics:

Control

- Feedback: “It’s too hard to start turning”

- Design Response: Adjust tail stabilizer angle to shift the center of pressure and / or body position.

Lift and Takeoff Speed

- Feedback: “I struggle to get up in light wind”

- Design Response: Increase foil surface area or change the airfoil to generate more lift.

Stability

- Feedback: “It feels twitchy at high speeds”

- Design Response: Use a stiffer mast construction and check if the foil is loosing stability due to turbulence, cavitation, etc.

Maneuverability

- Feedback: “I want tighter turns without losing speed”

- Design Response: Tweak foil outline and dihedral angle, possibly shift center of lift aft.

This translation layer is where engineering meets intuition. Something Airovex excels at through its cross-disciplinary design team and feedback loops with elite riders and users.

A case study about prototyping, simulation and

Let’s look at a case study that exemplifies this approach:

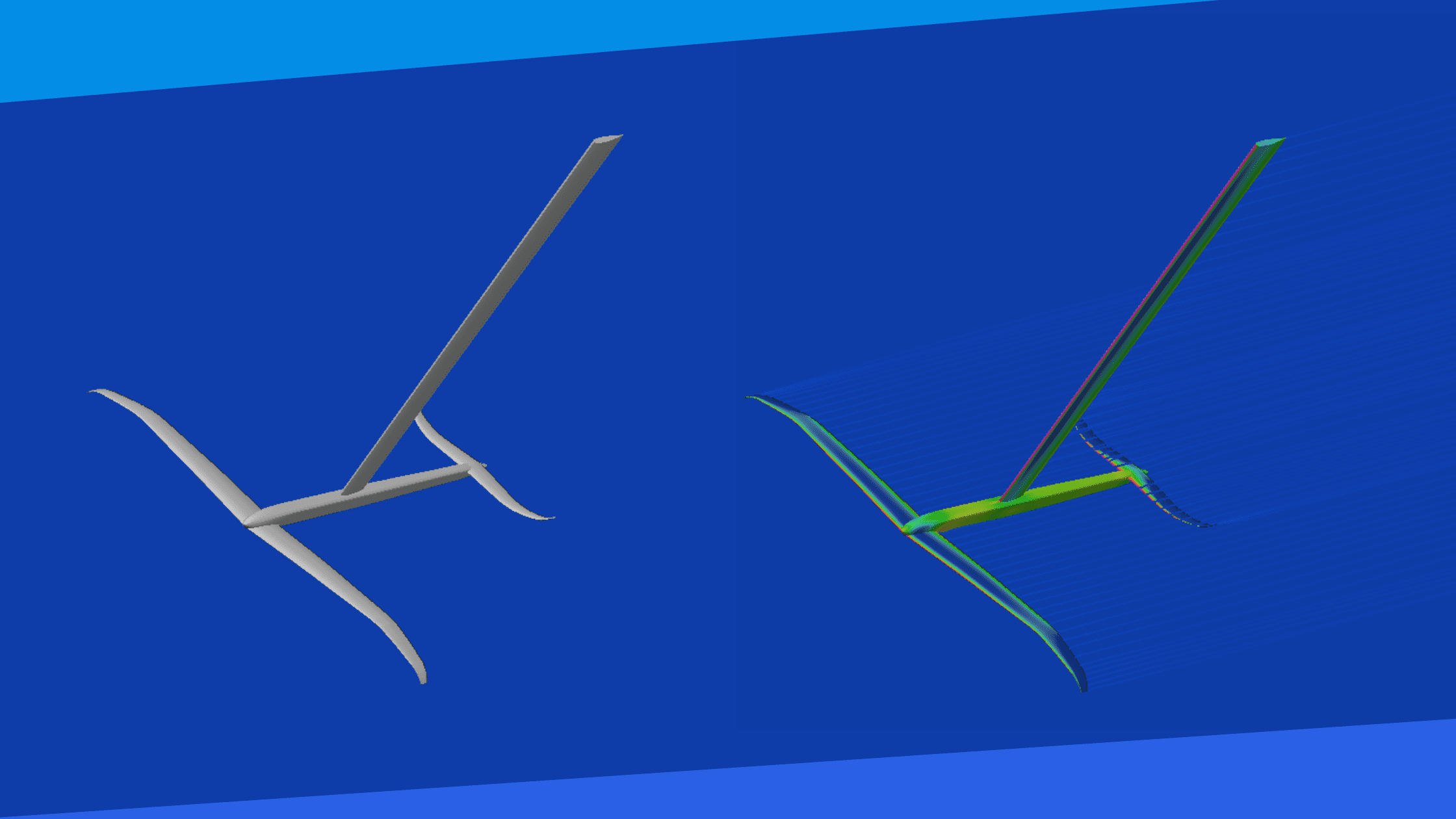

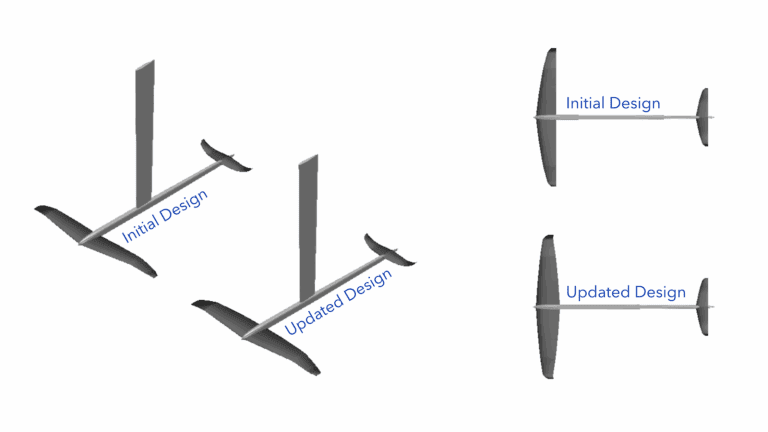

Multiple intermediate riders report that a current front foil model is sluggish to lift in 8–10 knot winds and feels “unturnable” in early, slow turns. So, we gather this feedback and previous performance data if available and develop the following design goal:

- Create a front hydrofoil that lifts earlier in low wind but still turns tightly even at the lower speed range without stalling.

Airovex’s Redesign Approach:

-

- Increase Surface Area: Boost front wing area by ~8% for earlier takeoffs.

-

- Lower Aspect Ratio: Drop from 9.50 to 8.25 to trade glide performance for a more agile roll behaviour.

-

- Foil Thickness Distribution: Shift max camber forward slightly for more initial lift.

-

- Wing Sweep Adjustment: Reduce sweep to allow for earlier takeoffs.

These suggested design changes should address the issues at hand. We then proceded to generate a CAD model that not only helps visualize these changes, but also prepares the geometry for simulations and prototyping. It will additionally help visualize how subtle tweaks can drive major handling differences.

Naturally all these changes imply a hit on other performance parameters. We’ll then have to validate if the issues were solved without a big toll at higher speed performance.

As you may already know, CAD designs no longer live alone. Modern hydrofoil development uses a tight loop of simulation-optimization loops, prototyping, and on-water validation once a CAD geometry seems to satisfy the requirements, at least digitally.

In other words, this process can be summarized:

- CFD Simulations allow for pre-testing of drag, lift coefficients, and keep in check cavitation thresholds of the proposed CAD geometry.

- Rapid Prototyping using CNC-milled cores or 3D-printed test foils lets engineers and designers trial variations as quickly as possible.

- Field Testing or Real-world test data, GPS logs, and user commentary shape the next round of tweaks if needed.

This hybrid workflow means faster iteration cycles, and more responsive design evolution. Sometimes, depending on the project and/or changes the whole iteration loop can happen as quickly as a few days or weeks after the model is validated via simulations.

Looking ahead, user-centric design in foiling could get even smarter:

Modular Systems where users swap in different wings and stabilizers for different conditions between races may not be too far from where the status quo is at the moment.

I have been asked whether AI or machine learning (ML) tools can predict optimal foil shapes based on rider weight, wind history, and GPS data. The answer to this, in my opinion, is very simple: They could do it, but they could also be very far from achieving it by suggesting a non-viable real world design. Turbulence modelling is something that is currently really hard to predict and physical tests may be necessary in some cases. You have to always check and validate their outputs and at least for the near term future, a human in the loop with enough knowledge and expertise on the subject will still be necessary.

Similarly, smart foils with embedded sensors feeding real-time performance data back to riders or designers for continuous improvement, just like a test-bed hydrofoil may not be that far off into the future as it may seem.

Just as in cycling or motorsport, feedback loops are tightening. Hydrofoil design isn’t just about flow,it’s about the rider’s feel and their ability to extract the maximum output from their equipment consistently.

So, in a nutshell

Hydrofoiling and wingfoiling are rapidly evolving sports and their gear needs to keep pace. By bringing the user into the heart of the design process, companies like us at Airovex aren’t just engineering better foils, we’re redefining what it means to co-create performance.

As technology and creativity continue to merge, the future of foiling looks not only faster and lighter, but smarter too!

Let’s create the future together.

Engineering is more than solving technical problems, it’s about shaping the future. We believe that by fostering collaboration, embracing creativity, and drawing on diverse perspectives, we can deliver solutions that don’t just meet today’s challenges but anticipate tomorrow’s opportunities.

Whether you’re a startup with a groundbreaking idea, an established company looking to push boundaries, or a team aiming to optimize performance, Airovex is here to help. Together, we can turn ambitious ideas into transformative realities.

Explore more about how we at Airovex are driving innovation on our Insights page.